Product Introduction

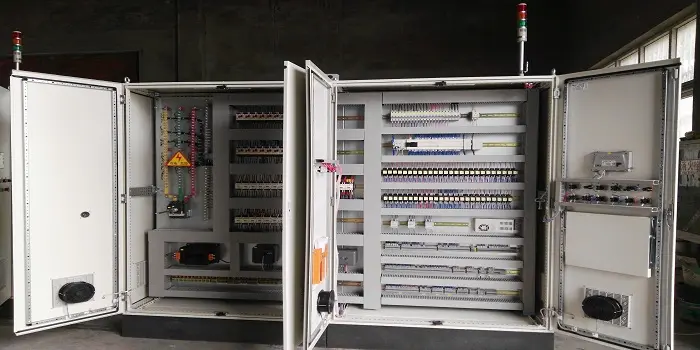

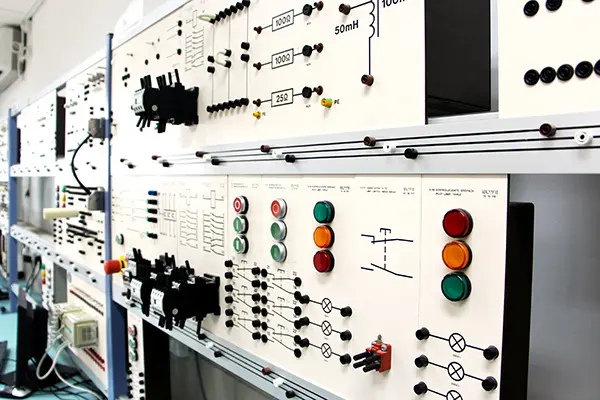

The control cabinet adopts Rittal to ensure the strength and thickness of the cabinet. It adopts computer color matching electrostatic spraying technology, which has strong adhesion, is not easy to fall off, has strong corrosion resistance and high finish.

01. Rittal cabinets can be divided into three series in terms of structure: ES cabinets (50% off profile cabinets), PS cabinets (90% off profile cabinets), and TS cabinets (160% off profile cabinets). The characteristic of Rittal cabinets is that they adopt profile frame structure. The cabinet frame is welded first, and then the top plate, bottom plate, side plate, door plate, and mounting plate are fixed to the frame with screws. The advantage of this is that the product has a modular structure and is easy to use.

02. Beautiful products. Rittal cabinets pursue the concept of perfection in both the use and appearance of industrial products. The sheet metal structure design and the matching of accessories are also very reasonable and scientific, forming a standardized matching design.

03. Easy to use. The design of the internal longitudinal beams, columns, cross beams, lines and the molded holes makes the installation easy and convenient for users.

0 4. Strong and durable, safe and reliable, the Rittal cabinet frame structure makes the structure stable, a single cabinet can bear 2000KG, no need to worry about installing any bulky devices;

0 5. At the same time, the material is carbon steel and stainless steel, and the default material thickness is 2.0mm for door panels, 2.5mm for mounting plates, and 1.5mm for cabinets;

06. The default surface treatment for carbon steel is plastic spraying, and phosphating primer treatment is done before plastic spraying. The color is RAL7035. The default surface treatment process for stainless steel is wire drawing.

Company Strength

Innovative design capabilities

Gather more than 10 experienced technical engineers with the ability of power distribution and automatic control design and software programming development;

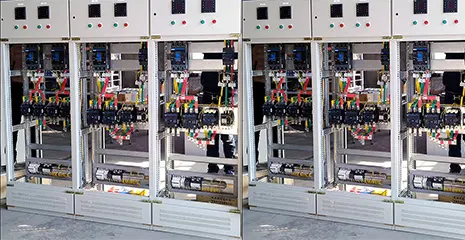

The two powerful forces joined forces to create Chen Yixin, which uses high intelligence to make the product structure and wiring more scientific, and the wiring inside the cabinet is reasonable and beautiful, showing the beauty of craftsmanship.

Production customization capabilities

With more than 10 years of experience in the production of low-voltage electrical equipment, we can customize exclusive automation control solutions according to customer needs;

We strictly implement the ISO9001 quality management system, all products have passed 3C certification, and the production progress nodes are tracked in time to ensure on-time delivery.

Quality and price guarantee system

Huapujie Electric has long-term cooperation with Siemens, Schneider, ABB, Rockwell and other brand component manufacturers, with genuine and high-quality configuration;

High-quality raw materials are purchased centrally, with lower costs, stable performance, and complete functions, and can be combined according to the actual control scale.

Technical collaboration support

Original technical support, collaborative product upgrade and optimization, establishment of a 7*24-hour rapid response mechanism, and full-time project engineers to guide operations at any time;

The project will be followed up by a dedicated project engineer from the early stage to the later stage to avoid information errors and the time required to familiarize yourself with the project again.

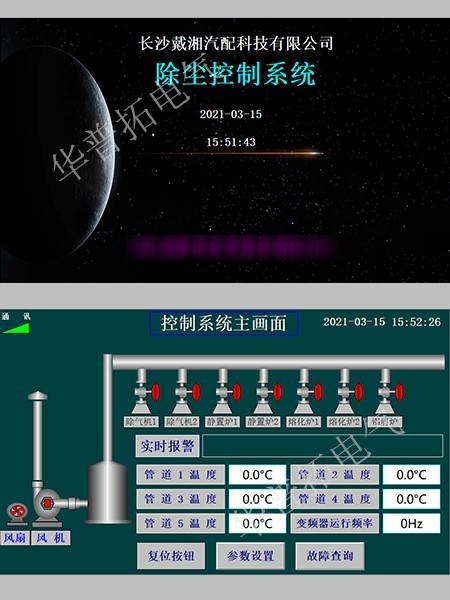

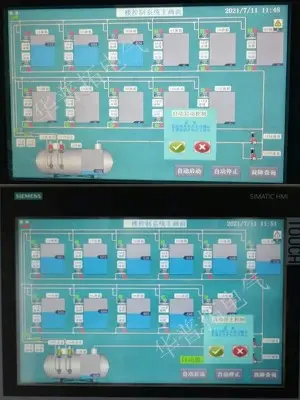

Intelligent Manufacturing / Industry 4.0

Intelligent Manufacturing / Industry 4.0 Motor Control Center MCC

Motor Control Center MCC Data Center

Data Center Environmental Industry

Environmental Industry Industrial Machinery

Industrial Machinery New Energy

New Energy Pharmaceutical Manufacturing

Pharmaceutical Manufacturing Petroleum & Chemical

Petroleum & Chemical Marine & Offshore & Ship

Marine & Offshore & Ship Food processing / agricultural production

Food processing / agricultural production