Product Introduction

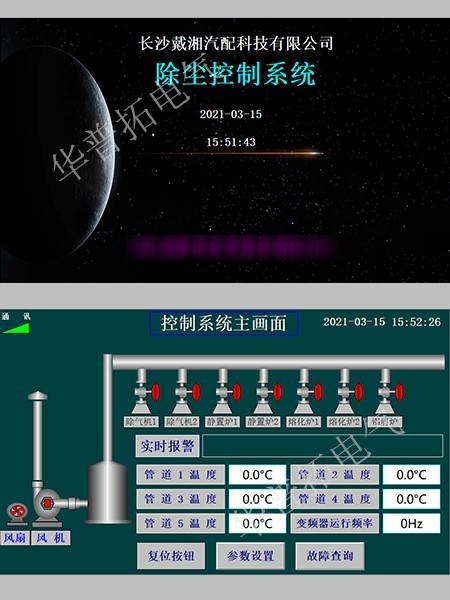

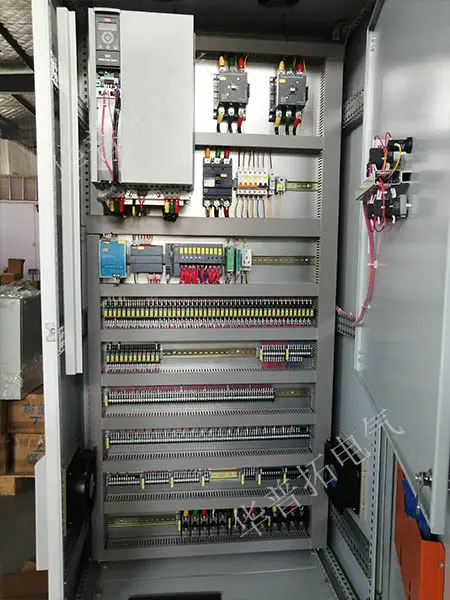

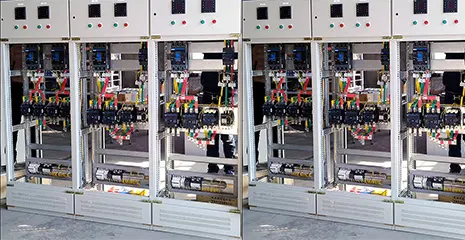

The frequency converter cabinet of the central cleaning system is designed, produced, assembled and debugged by Kunshan Huapujie Electric Co., Ltd. It is used to control the dust removal control of the central dust collection system.

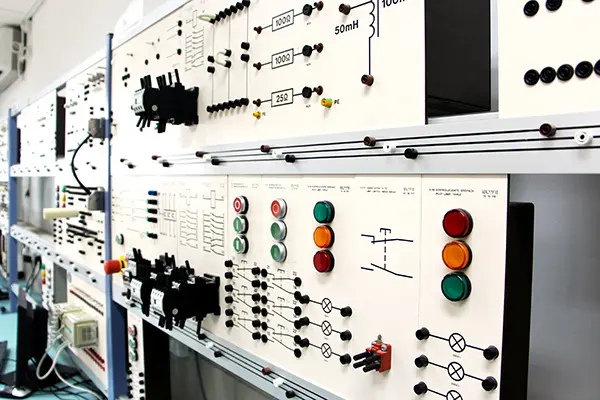

This project is a centralized dust removal project for a pharmaceutical factory in Taizhou. There are 4 PLC frequency conversion cabinets in total. The control cabinet has a front-opening door, the cabinet size is H2200*W900*D600MM, and the plate is 2.0MM thick carbon steel plate.

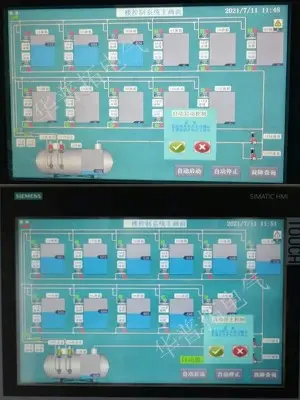

The fourth electric control cabinet is equipped with a Siemens HMI touch screen.

INVT FC111 series inverter has mature functions and stable performance. It is also a commonly used inverter in China. It has high cost performance.

The frequency conversion cabinet can minimize the impact of high-power water pumps and fans on the power grid and the voltage drop of the main power grid, with significant power saving effect .

HV central dust removal system is used to control the dust collection system of pharmaceutical factories. The inverters are 18.5KW 30KW 37KW and 55KW. The indicator lights and instruments can provide feedback on dust concentration, wind speed and pressure, differential pressure, fan bearing temperature, etc.

Frequency conversion speed regulation function of frequency conversion control cabinet The frequency conversion control cabinet control panel is equipped with a potentiometer for frequency conversion speed regulation, which can send command signals to the motor according to the output frequency of the operator to control the speed of the motor. Some products in the frequency conversion control cabinet are equipped with a power frequency switching function to ensure that when the frequency converter fails, the motor is switched back to the power frequency power supply through the automatic control circuit.

Advantages of INVT inverter central cleaning system control cabinet:

1) PLC automatic control, module collects signals and outputs.

2) Reduce energy consumption, frequency conversion control, save energy and reduce costs.

3) Safe production, fault alarm to cope with long-distance and complex working conditions on site.

4) Wide application Typical applications are constant pressure water supply, air compressor, fan pump control type liquid level control, pressure control, temperature control, etc.

Company Strength

Innovative design capabilities

Gather more than 10 experienced technical engineers with the ability of power distribution and automatic control design and software programming development;

The two powerful forces joined forces to create Chen Yixin, which uses high intelligence to make the product structure and wiring more scientific, and the wiring inside the cabinet is reasonable and beautiful, showing the beauty of craftsmanship.

Production customization capabilities

With more than 10 years of experience in the production of low-voltage electrical equipment, we can customize exclusive automation control solutions according to customer needs;

We strictly implement the ISO9001 quality management system, all products have passed 3C certification, and the production progress nodes are tracked in time to ensure on-time delivery.

Quality and price guarantee system

Huapujie Electric has long-term cooperation with Siemens, Schneider, ABB, Rockwell and other brand component manufacturers, with genuine and high-quality configuration;

High-quality raw materials are purchased centrally, with lower costs, stable performance, and complete functions, and can be combined according to the actual control scale.

Technical collaboration support

Original technical support, collaborative product upgrade and optimization, establishment of a 7*24-hour rapid response mechanism, and full-time project engineers to guide operations at any time;

The project will be followed up by a dedicated project engineer from the early stage to the later stage to avoid information errors and the time required to familiarize yourself with the project again.

Intelligent Manufacturing / Industry 4.0

Intelligent Manufacturing / Industry 4.0 Motor Control Center MCC

Motor Control Center MCC Data Center

Data Center Environmental Industry

Environmental Industry Industrial Machinery

Industrial Machinery New Energy

New Energy Pharmaceutical Manufacturing

Pharmaceutical Manufacturing Petroleum & Chemical

Petroleum & Chemical Marine & Offshore & Ship

Marine & Offshore & Ship Food processing / agricultural production

Food processing / agricultural production