What are the requirements for the design and production of programmable control cabinets in the pharmaceutical industry

project introduction

What are the requirements for the design and production of programmable control cabinets in the pharmaceutical industry

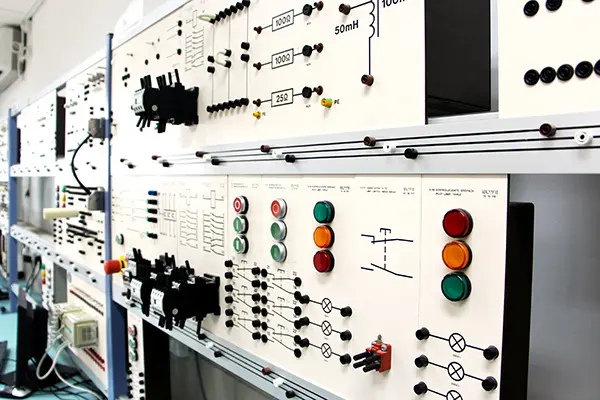

The electrical cabinets used in the pharmaceutical manufacturing industry can be roughly divided into the following types due to their different functions: 1. Integrated dust removal equipment electrical control cabinets. During the production and processing of pharmaceutical workshops, dust is generated, and various components in these particles mix together, posing risks of explosion and harm to human health. Dust must be removed through dust removal equipment. When designing electrical cabinets at this time, explosion-proof cabinet types with a protection level of IP65 or above will be considered. If the equipment is placed outdoors, such high protection is not necessary. 2. Pharmaceutical equipment system control cabinet, an electrical cabinet that automatically controls the start, stop, and operation of equipment. These types of electrical cabinets are installed in the workshop, with high protection level requirements. Generally, IP55 and stainless steel materials are required, and explosion-proof cabinets are also used for stricter ones. 3. And control cabinets for water treatment equipment in the pharmaceutical industry. Paired with programmable modules and touch screens for control. Realize editable automation control effects.

Application Highlights

● Made of stainless steel material, with a high protection level of IP55 or above, we customize control cabinets for pharmaceutical factories to ensure the safety of equipment use.

● Siemens imported PLC programmable modules, G120X series imported dedicated frequency converters, Schneider and other mature brand low-voltage components. More stable and secure.

● Senior engineers conduct on-site debugging and regular equipment maintenance to ensure stable operation.

● PLC program automation control. Switch signal conversion. More convenient.

● Reasonable layout, beautiful installation and wiring, improved overall appearance, and more reliable.

● The entire control system is easy to operate and has high safety performance.

Intelligent Manufacturing / Industry 4.0

Intelligent Manufacturing / Industry 4.0 Motor Control Center MCC

Motor Control Center MCC Data Center

Data Center Environmental Industry

Environmental Industry Industrial Machinery

Industrial Machinery New Energy

New Energy Pharmaceutical Manufacturing

Pharmaceutical Manufacturing Petroleum & Chemical

Petroleum & Chemical Marine & Offshore & Ship

Marine & Offshore & Ship Food processing / agricultural production

Food processing / agricultural production