Case study of PLC system control cabinet for packaging sugar powder collection in Nanning Sugar Industry Bridge Sugar Factory

project introduction

Case study of PLC system control cabinet for packaging sugar powder collection in Nanning Sugar Industry Bridge Sugar Factory

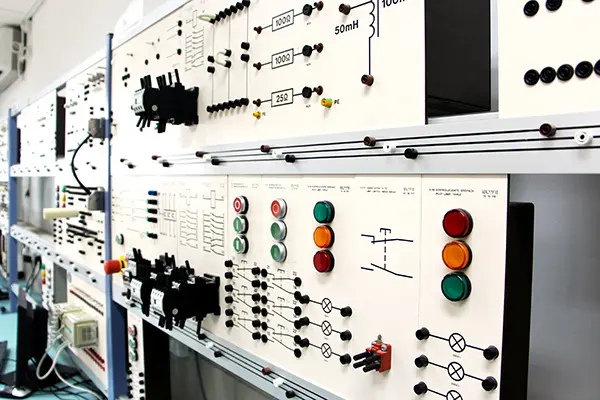

The left picture shows the control cabinet of the sugar powder collection PLC system. The PLC system control cabinet is not large in size, occupies a small space, and is convenient for on-site handling. The main components are Siemens PLC modules, Mingwei DC power supply, Chint circuit breakers, fuses, and wiring terminals. The cabinet door is equipped with Siemens touch screens and branded components, which provide more stable performance.

Application Highlights

● Reasonable design and beautiful layout. Small size control cabinet, single door.

● Stable performance and scalability. Siemens PLC programmable controller module, real-time reading of equipment operation data. Act according to the specified program.

● Energy saving and consumption reducing, smooth start-up. PLC controllers and frequency converters have low power consumption. Energy conservation and green environmental protection.

● The human-machine interface HMI touch screen operation is convenient and fast.

● PLC system programming software configuration. After the installation of the PLC system control cabinet on site, Huapu Tuo electrical engineers still need to debug and configure the PLC system and on-site equipment. Visually observe the status of sugar powder collection through PLC programming interface.

● Automatically issuing alerts is safe and reliable. The system will issue an alarm when the equipment malfunctions, reminding staff to promptly troubleshoot and ensure smooth operation of the equipment.

Intelligent Manufacturing / Industry 4.0

Intelligent Manufacturing / Industry 4.0 Motor Control Center MCC

Motor Control Center MCC Data Center

Data Center Environmental Industry

Environmental Industry Industrial Machinery

Industrial Machinery New Energy

New Energy Pharmaceutical Manufacturing

Pharmaceutical Manufacturing Petroleum & Chemical

Petroleum & Chemical Marine & Offshore & Ship

Marine & Offshore & Ship Food processing / agricultural production

Food processing / agricultural production