In the realm of industrial automation, the Motor Starter Control Panel plays a critical role in ensuring operational efficiency and equipment longevity. According to a recent report by Markets and Markets, the global industrial automation market is projected to reach $214 billion by 2026, highlighting the growing significance of advanced motor control technologies. Motor Starter Control Panels are essential for regulating motors’ startup sequences, safeguarding against overloads, and improving energy efficiency. With approximately 30% of industrial energy consumption attributed to electric motors, optimizing their performance through proper control panel configurations can lead to significant cost savings and enhanced productivity. As industries continue to embrace automation and smart technologies, understanding the essentials of Motor Starter Control Panels becomes imperative for achieving optimal performance and reliability in machinery operations.

Motor starters are critical components in industrial applications, serving to control the starting and stopping of electric motors. The fundamental types of motor starters include

Direct-On-Line (DOL),

Star-Delta, and

Auto-Transformers, each offering distinct advantages based on the application requirements. According to a report by the International Electrotechnical Commission (IEC), DOL starters are most commonly used for small motors, providing a simple and cost-effective solution, whereas Star-Delta starters are recommended for larger motors to reduce inrush current during startup, enhancing performance and prolonging motor life.

In terms of functionality, each starter type plays a crucial role in optimizing motor performance. DOL starters directly connect the motor to the power supply, allowing full voltage to the motor from the start but can cause high starting currents. Star-Delta starters, in contrast, initially connect the motor in a star configuration to limit voltage and reduce starting current before switching to delta for full operation.

According to a market analysis by Research and Markets, the increasing demand for energy-efficient motor control technology is driving the adoption of advanced motor starters, which are projected to grow at a CAGR of 4.6% from 2022 to 2027. Understanding these types and their respective functions is essential for engineers aiming to enhance operational efficiency and meet stringent industry standards.

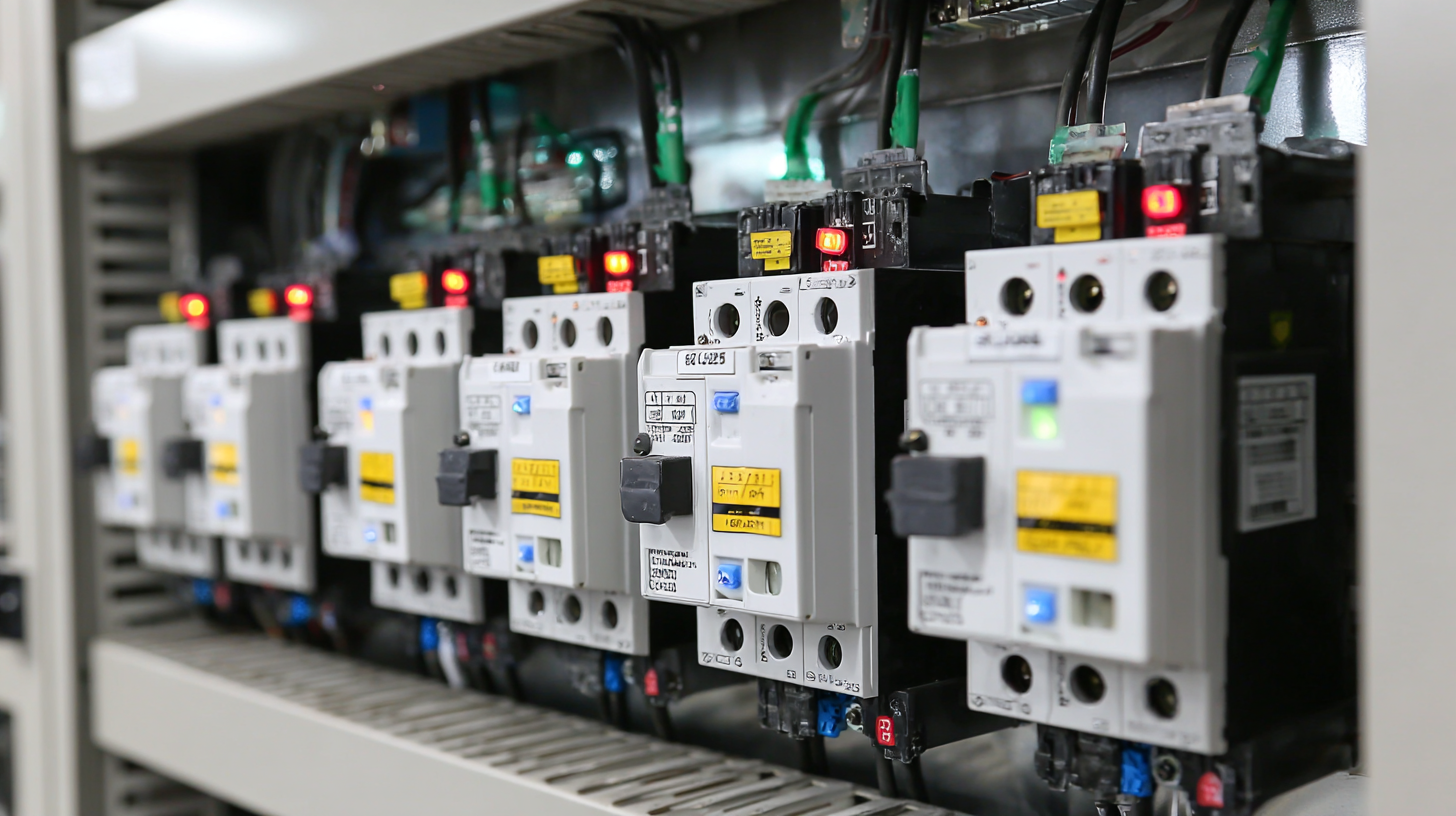

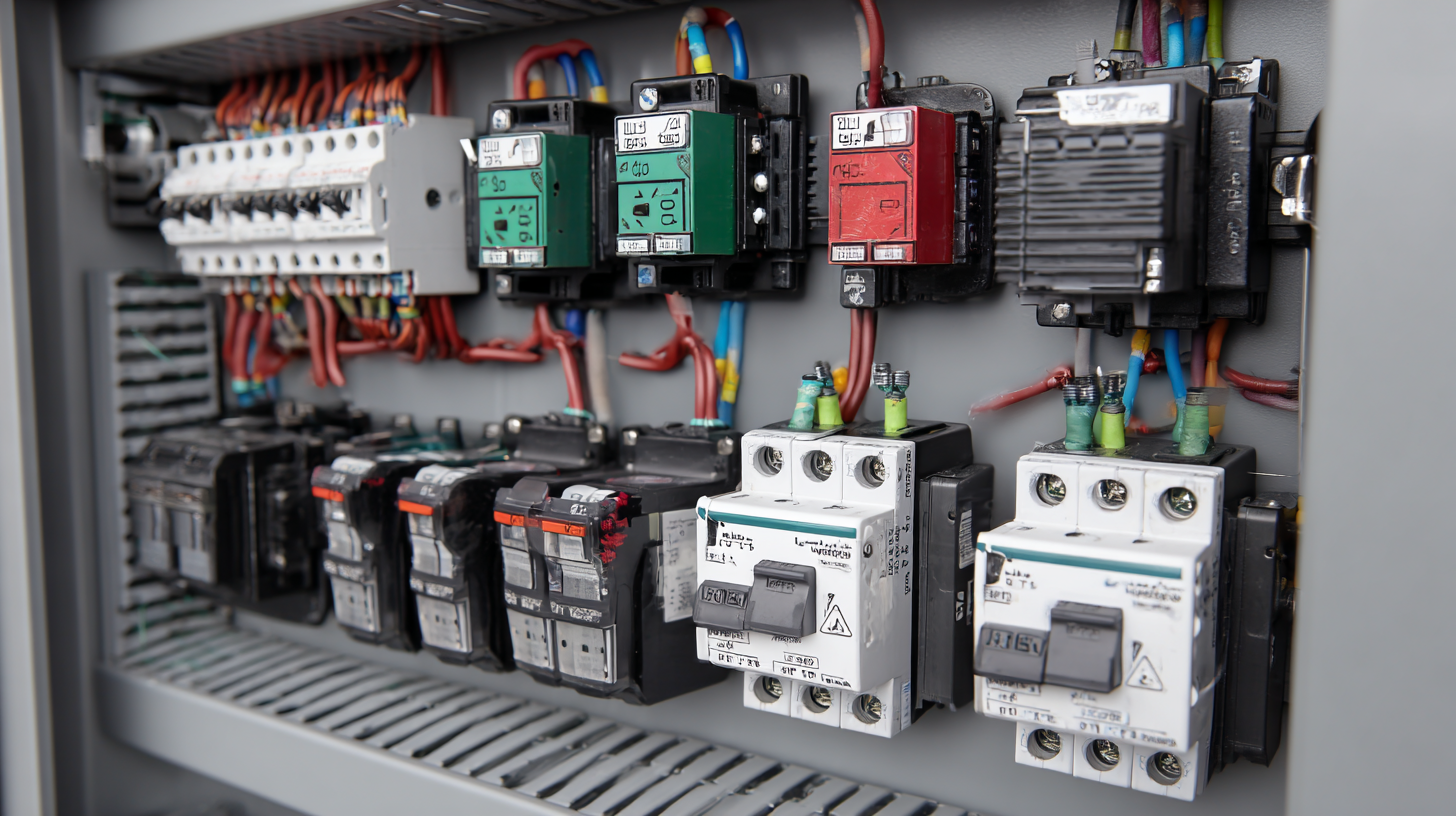

Motor starter control panels are critical components in various industrial applications, serving to initiate, protect, and control electric motors. Understanding the key components of these panels is essential for ensuring optimal performance. At the heart of the control panel lies the motor starter itself, typically composed of contactors and overload relays. According to a report by the Electric Power Research Institute (EPRI), proper selection and maintenance of these starters can reduce operational costs by up to 15% by minimizing downtime and energy waste.

Another integral part of the motor starter control panel is the control circuitry, which includes fuses, circuit breakers, and relays. These devices play a vital role in protecting the motor from conditions such as overloads and short circuits. The National Electrical Manufacturers Association (NEMA) suggests that incorporating advanced protective relays can enhance system reliability by up to 20%, ultimately leading to fewer maintenance interventions. Additionally, control panels often feature timers and sensors that optimize motor operation, contributing to enhanced energy efficiency. Leveraging these components effectively can result in significant savings and improved longevity of motor equipment in demanding environments.

| Component | Function | Importance |

|---|---|---|

| Contactors | Used to control the power to the motor | Essential for safe operation and power control |

| Overload Relays | Protects motor from overheating due to excessive current | Crucial for protecting motor integrity |

| Control Switches | Enables operators to start or stop the motor | Vital for manual control and safety |

| Fuses/Circuit Breakers | Provides overcurrent protection | Essential for preventing electrical faults |

| Control Relays | Facilitates control logic and signal routing | Important for automation and control systems |

When it comes to motor control, understanding the differences between Direct-on-Line (DOL) starters and soft starters is crucial for optimal performance. DOL starters provide a straightforward approach, supplying the full voltage directly to the motor. This method is simple and cost-effective, making it suitable for applications where high starting torque is required. However, the sudden high inrush current can lead to mechanical stress, potentially shortening the motor’s lifespan.

When it comes to motor control, understanding the differences between Direct-on-Line (DOL) starters and soft starters is crucial for optimal performance. DOL starters provide a straightforward approach, supplying the full voltage directly to the motor. This method is simple and cost-effective, making it suitable for applications where high starting torque is required. However, the sudden high inrush current can lead to mechanical stress, potentially shortening the motor’s lifespan.

On the other hand, soft starters employ a more sophisticated control strategy to gradually ramp up the voltage, reducing the initial surge of current. This provides a smoother start, minimizing mechanical stress and electrical disturbances. Soft starters are particularly beneficial in applications with heavy loads or those requiring precise control, as they allow for gradual acceleration and deceleration.

Tip: If your application involves frequent starts and stops, consider investing in a soft starter. This not only enhances equipment longevity but also improves energy efficiency. Additionally, always assess your specific application needs before deciding on the type of starter. For instance, environments with high mechanical loads may benefit more from a soft starter's gentle approach than a DOL starter's direct method.

When it comes to motor starter control panels, safety features are of paramount importance. Understanding these safety mechanisms can significantly reduce the risks associated with operating electrical motors. One essential feature is the overload relay, which protects the motor from overheating by disconnecting the power supply when the current exceeds a predetermined level. This not only prevents damage to the motor but also extends its lifespan, ensuring reliable performance over time.

Another critical safety aspect is the incorporation of emergency stop buttons and safety interlocks. These features allow for immediate disconnection of power in case of an emergency, providing an extra layer of protection for operators and equipment. Safety interlocks ensure that conditions are safe before a motor can be activated, thereby preventing accidental starts that could lead to injuries or equipment damage. By understanding and implementing these safety features in motor starter control panels, organizations can create a safer working environment and enhance the overall reliability of their motor systems.

Maintaining optimal performance of motor starter systems requires a comprehensive understanding of best practices that enhance their reliability and efficiency. Regular inspections and preventive maintenance are critical components of an effective strategy. According to the Electrical Engineering and Automation journal, nearly 30% of motor failures can be traced back to inadequate maintenance of starter control systems. This underscores the necessity for routine checks, which should include monitoring the thermal overload relays and ensuring proper connections.

Furthermore, environmental factors play a significant role in the operation of motor starters. A report from the International Electrotechnical Commission highlights that over 40% of motor performance issues are linked to environmental conditions, such as excessive heat and humidity. These conditions can lead to premature wear and tear on electrical components. To combat this, facilities should implement climate control measures and regularly clean and inspect panels to minimize dust and corrosion, thus extending the lifespan of motor starter systems. By adhering to these best practices, organizations can significantly enhance operational efficiency and reduce downtime.