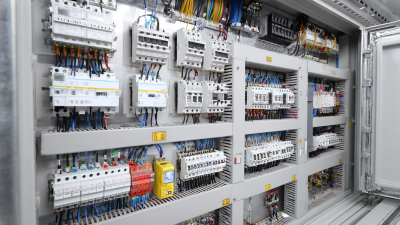

In today's rapidly evolving industrial landscape, the significance of MCC electrical systems cannot be overstated. Motor Control Centers (MCCs) serve as the backbone of modern automation, providing efficient and centralized control of motors and electrical equipment. As industries strive for increased productivity, reliability, and safety, understanding how to effectively implement and utilize MCC electrical systems becomes essential. This guide explores crucial elements that make MCC electrical indispensable for contemporary industrial applications, ranging from their role in improving operational efficiency to enhancing safety measures. By delving into the complexities and advantages of MCC electrical systems, we aim to equip you with the knowledge needed to optimize your industrial processes and stay ahead in an increasingly competitive market.

Motor Control Centers (MCCs) play an indispensable role in modern industrial applications, particularly in streamlining automation processes. As industries strive for increased efficiency and productivity, MCCs serve as centralized systems that control and monitor various motor functions, thereby facilitating seamless operations. The global motor control center market size was valued at USD 6.18 billion in 2024 and is projected to grow to USD 6.57 billion in 2025, highlighting the growing reliance on these systems in various sectors.

One of the critical advantages of MCCs is their ability to optimize power distribution and reduce downtime. By integrating advanced control technologies, MCCs enable real-time monitoring and diagnostics, allowing operators to identify issues before they escalate. This proactive approach not only enhances operational efficiency but also drives energy savings—a vital consideration in today’s cost-conscious industrial landscape.

**Tips for Implementation:** Consider investing in scalable MCC solutions tailored to your specific operational needs for better adaptability as your business grows. Regularly updating control software can also help in leveraging the latest advancements, ensuring your systems are efficient and compliant with industry standards. Additionally, training personnel on MCC functionalities is crucial for maximizing the performance and safety of your industrial processes.

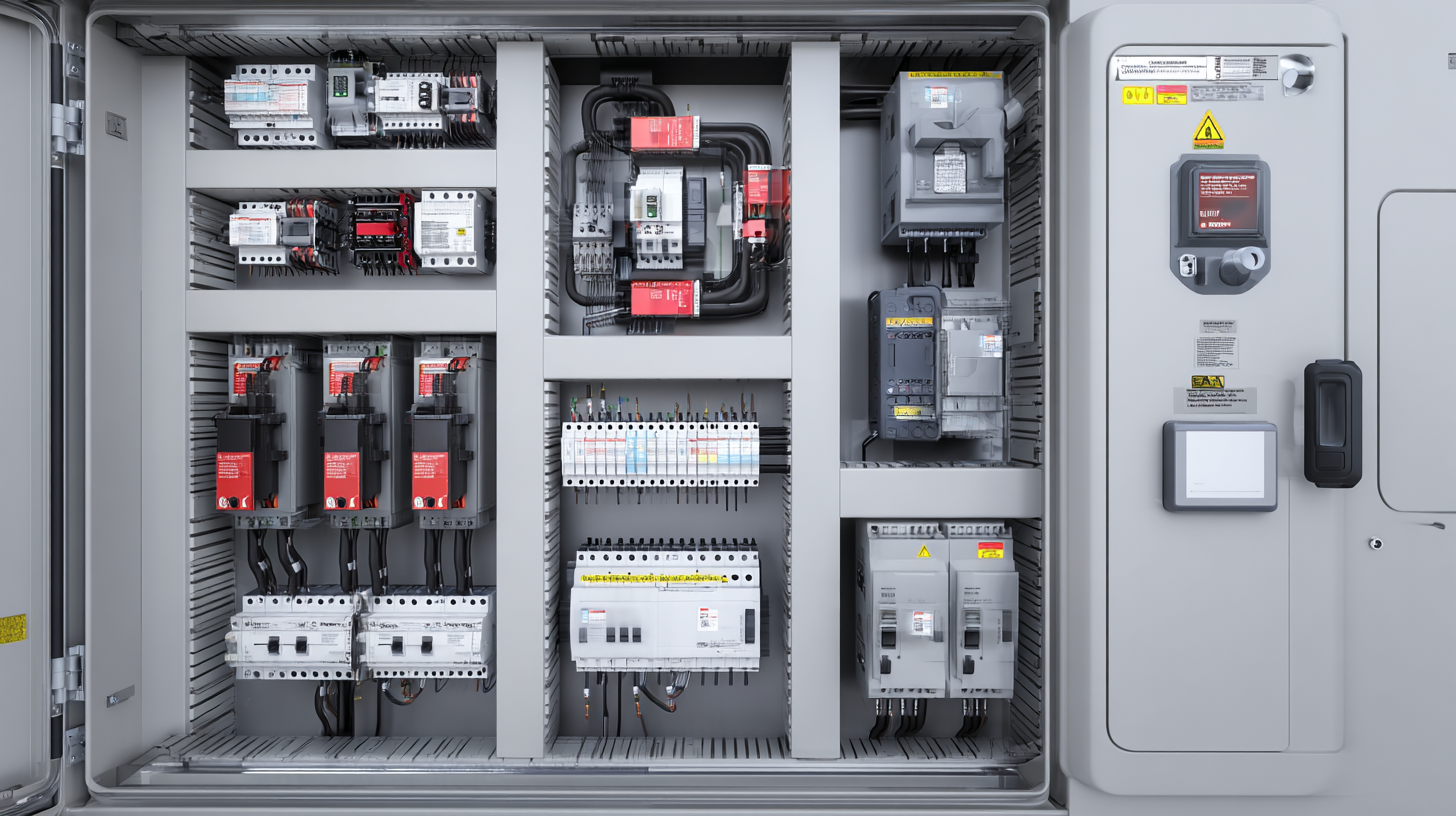

The integration of MCC electrical systems in modern industrial applications is vital for enhancing operational efficiency and sustainability in manufacturing environments. One major benefit of MCC systems is their ability to streamline maintenance processes, significantly reducing downtime. For instance, recent advancements in modular switchboards and motor control center systems demonstrate how such innovations can save on maintenance time, allowing operators to focus on productivity rather than equipment failures. This efficiency is crucial as industries strive to minimize operational costs while maximizing output.

Furthermore, MCC systems contribute to improved safety standards in manufacturing settings. By centralizing control mechanisms, they provide a clear framework for monitoring and managing electrical systems, which mitigates risks associated with equipment operation. In addition, these systems support eco-friendly practices, aligning with the industry's shift towards sustainability. The use of advanced technologies can also complement environmental strategies, such as optimizing energy usage in response to varying operational demands, thereby enhancing the overall performance of manufacturing processes. This integration of MCC electrical systems is not just an operational necessity; it is a strategic approach to ensuring long-term sustainability and safety in the industrial sector.

| Benefit | Description | Impact on Manufacturing |

|---|---|---|

| Improved Efficiency | MCC systems streamline power distribution and monitoring, leading to reduced downtime. | Higher productivity levels and optimized operational costs. |

| Enhanced Safety | Integrated safety mechanisms in MCC systems minimize risk of electrical hazards. | Safer work environment and reduced accident rates. |

| Scalability | MCC designs can easily expand to meet increasing power demands. | Flexibility to adapt to growing manufacturing needs without major overhauls. |

| Cost Savings | Efficient power management leads to lower energy costs over time. | Increased profitability through reduced operational expenses. |

| Advanced Monitoring | Real-time data on power consumption and system performance. | Better decision-making and proactive maintenance strategies. |

The impact of MCC electrical systems on energy efficiency and cost reduction in modern industrial applications cannot be overstated. With the global electrical equipment market projected to grow from $1,660.2 billion in 2025 to $3,326 billion by 2032, at a compound annual growth rate (CAGR) of 10.4%, industries are increasingly looking for solutions that enhance energy efficiency while reducing operational costs.

Integrating MCC systems allows industries to optimize energy consumption, leveraging advanced control technologies that reduce waste and improve overall system reliability.

Tip: Implementing an energy management system alongside MCC can further maximize savings and operational efficiency. According to a McKinsey report on industrial decarbonization, timely planning and action can mature technologies and lower the costs associated with energy transition in industrial sectors.

Moreover, the rise in electricity utilization, labeled as the "white power" era, emphasizes the shift towards cleaner energy sources. Industries adopting electric technologies, such as electric vehicles and energy-efficient machinery, participate in this transition, ultimately enhancing their competitiveness in the market. With the global industrial IoT platform market expected to reach $12.597 billion by 2032, the integration of MCC in these systems is crucial for driving energy efficiency and supporting sustainable industrial practices.

MCC Electrical has proven itself to be indispensable in various industrial sectors, showcasing its versatility through multiple case studies. In the manufacturing industry, for instance, the implementation of MCC systems has streamlined production processes by allowing for centralized control of motor operations. A notable case involved a large automobile assembly plant, where MCC Electrical facilitated the synchronization of conveyor systems, resulting in a 20% increase in assembly line efficiency. The enhanced control and monitoring capabilities provided by MCC systems enable manufacturers to quickly adapt to changing production requirements.

In the energy sector, a renewable energy plant successfully integrated MCC Electrical to optimize their turbine control systems. By employing advanced MCC configurations, the plant improved its operational reliability and reduced downtime caused by maintenance issues. As a result, energy production rose by 15%, significantly contributing to the region's power supply. These examples highlight the crucial role MCC Electrical plays in enhancing operational efficiency and reliability across diverse industrial applications, shedding light on its growing importance in the modern industrial landscape.

The future of MCC electrical technology is poised for significant transformation as industries seek to enhance productivity and efficiency. With the advent of smart manufacturing, Modular Control Centers (MCC) are becoming increasingly integrated with advanced technologies such as IoT, AI, and predictive analytics. This integration not only allows for real-time monitoring and control of electrical systems but also facilitates data-driven decision-making. As a result, industries can optimize their operations, minimize downtime, and respond swiftly to changing market demands.

Moreover, as sustainability becomes a critical focus in industrial applications, MCC technology is evolving to support energy efficiency initiatives. Future trends indicate a shift toward greener technologies, incorporating renewable energy sources and energy management systems within MCC frameworks. This not only helps in reducing operational costs but also aligns with global sustainability goals. As these advancements continue to unfold, MCC electrical technology will not only remain essential but also redefine the standards of industrial productivity in the years to come.