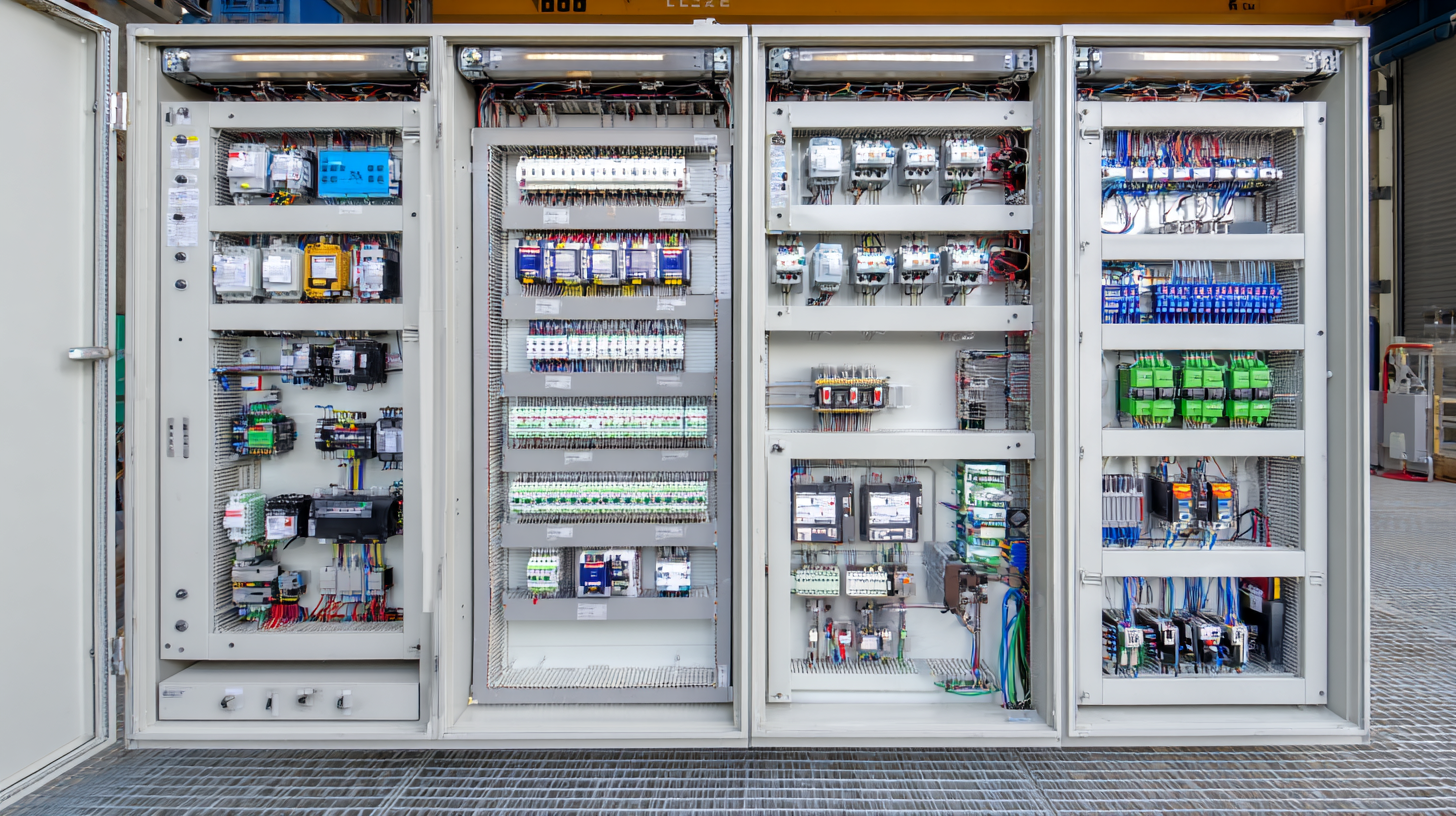

In today's fast-paced industrial landscape, the efficiency of electrical systems plays a critical role in operational success, and GRP Electric Cabinets have emerged as a vital component in this equation. According to a recent report by MarketsandMarkets, the global switchgear market, which includes GRP Electric Cabinets, is projected to reach $147.3 billion by 2025, reflecting a compounded annual growth rate of 7.8%. This surge underscores the growing reliance on advanced electrical infrastructure to support various applications, from renewable energy solutions to smart grid technologies. To capitalize on these trends and enhance operational efficiency, organizations must adopt best practices in the utilization and maintenance of GRP Electric Cabinets. This blog presents seven essential tips aimed at maximizing the effectiveness of these crucial components, ensuring reliability, safety, and improved performance in your operations.

When it comes to maximizing the efficiency of your GRP electric cabinets, choosing the right location is crucial. First and foremost, consider accessibility; the cabinets should be placed where maintenance personnel can easily reach them without obstructions. This not only enhances efficiency during routine checks and repairs but also ensures a quick response in case of emergencies. Aim for a location that allows for safe maneuvering around the cabinet, reducing potential hazards.

Furthermore, pay attention to environmental factors such as temperature and humidity. GRP electric cabinets are designed to protect electrical components, but extreme conditions can still impact their performance. Positioning these cabinets in a climate-controlled area can prevent overheating and moisture-related issues that could compromise the equipment inside. Additionally, consider proximity to other electrical systems; a consolidated approach reduces the length of wiring runs, minimizing energy losses and improving overall operational efficiency. By carefully selecting the location for your GRP electric cabinets, you lay the groundwork for a well-organized and efficient operation.

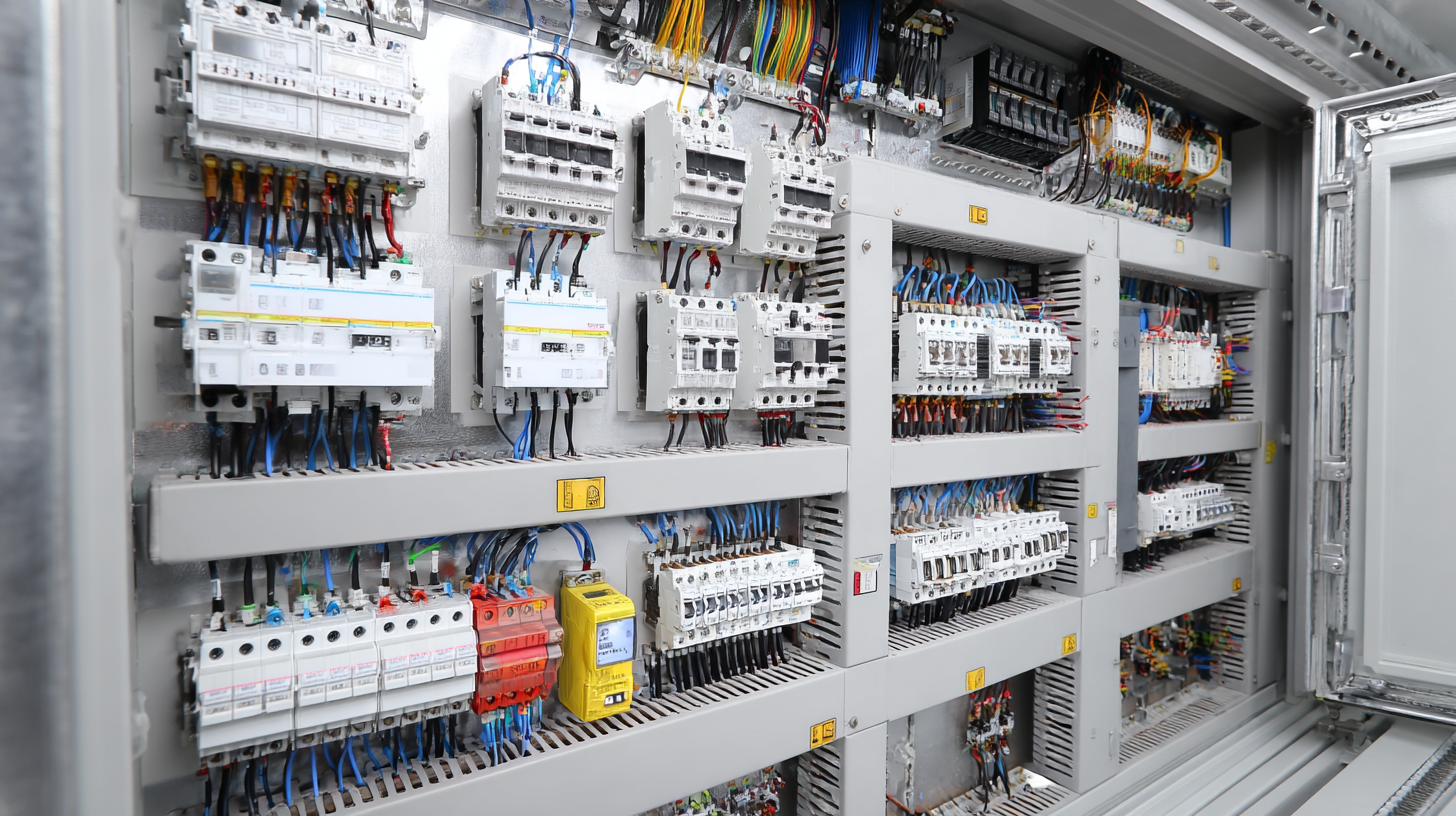

Proper ventilation and temperature control are critical components in maximizing the efficiency of GRP electric cabinets. According to a report by the International Electrotechnical Commission (IEC), electrical equipment operates optimally within a temperature range of 20-30 degrees Celsius. Deviations outside this range can lead to diminished performance, increased wear, or even catastrophic failures. Implementing effective ventilation systems ensures a consistent flow of air, reducing the risk of overheating, which can be especially problematic in industries where cabinets are subjected to high ambient temperatures or limited airflow.

Moreover, a recent study published by the Electric Power Research Institute (EPRI) highlighted that proper temperature management could extend the lifespan of electrical components by up to 30%. For GRP cabinets specifically, utilizing fans or heat exchangers can significantly improve internal air quality and maintain stable temperatures. These measures not only enhance the reliability of electrical systems but also reduce maintenance costs associated with overheating damage. By investing in adequate ventilation and temperature control solutions, businesses can ensure that their operations run smoothly and efficiently, safeguarding their investments in electrical infrastructure.

| Tip Number | Tip Description | Importance Level | Implementation Difficulty |

|---|---|---|---|

| 1 | Ensure proper ventilation to prevent overheating. | High | Moderate |

| 2 | Utilize temperature monitoring systems. | High | Easy |

| 3 | Schedule regular maintenance checks. | Medium | Moderate |

| 4 | Use enclosures with appropriate IP ratings. | High | High |

| 5 | Optimize airflow with fans or vents. | Medium | Moderate |

| 6 | Ensure easy access for maintenance and monitoring. | High | Easy |

| 7 | Educate staff on proper usage and monitoring. | Medium | Easy |

Regular maintenance schedules are integral to ensuring the longevity and efficiency of GRP electric cabinets. Many organizations overlook this crucial aspect, often waiting for issues to arise before addressing them. By implementing routine maintenance, facilities can identify potential problems before they escalate, thus avoiding costly repairs and operational downtime. Scheduled inspections allow for the assessment of components such as seals, junction boxes, and wiring, ensuring they are in optimal condition to withstand environmental pressures.

Additionally, regular cleaning and servicing of GRP cabinets can enhance their performance. Dust and debris accumulation can lead to overheating or reduced functionality of electrical systems. Maintenance activities should include thorough cleaning of the cabinet interiors and exteriors, followed by checks on ventilation systems to ensure proper airflow. Keeping detailed records of maintenance activities not only helps in compliance with industry standards but also aids in tracking performance over time, making it easier to spot trends and make informed decisions about upgrades or replacements. Consistent upkeep not only extends the lifespan of these critical assets but also optimizes operational efficiency, ultimately contributing to a more resilient and productive work environment.

Effective cable management and layout in grp electric cabinets are crucial for optimizing operational efficiency. According to a report by Data Center Dynamics,

poor cable management can lead to increased maintenance time by up to 25%, significantly hindering operational performance. To counteract this, implementing

structured cabling systems can streamline connections and ensure that cables are organized systematically. Utilizing cable trays and labeling systems not only reduces clutter

but also enhances visibility, making it easier for technicians to troubleshoot issues quickly.

Moreover, an insightful study by the National Electrical Contractors Association highlights that proper layout arrangement can reduce energy consumption by 15%. By strategically planning the layout of

grp electric cabinets, companies can minimize heat buildup and improve airflow, ultimately leading to lower operational costs and longer equipment lifespan. Adopting best practices

in cable management paired with an efficient layout can create a safer and more effective working environment, allowing businesses to thrive in a competitive landscape.

Integrating smart technology into GRP electric cabinets can significantly enhance monitoring abilities and operational efficiency. According to a recent report by the International Energy Agency (IEA), integrating smart technologies can improve energy efficiency by up to 10-30% in industrial applications. With real-time monitoring capabilities, facility managers can track energy consumption patterns, analyze performance metrics, and receive alerts on any anomalies. This proactive approach aids in optimizing power usage and reducing operational costs, thus enabling businesses to save resources without sacrificing performance.

Moreover, a study from the Institute of Electrical and Electronics Engineers (IEEE) highlights that facilities implementing smart monitoring systems can enhance maintenance schedules, reducing downtime by as much as 25%. By employing IoT-enabled sensors within GRP electric cabinets, organizations can facilitate predictive maintenance strategies, allowing them to address potential failures before they occur. This not only maximizes the lifespan of equipment but also improves overall productivity, enabling a more streamlined operation that is both agile and responsive to changing demands in the market.