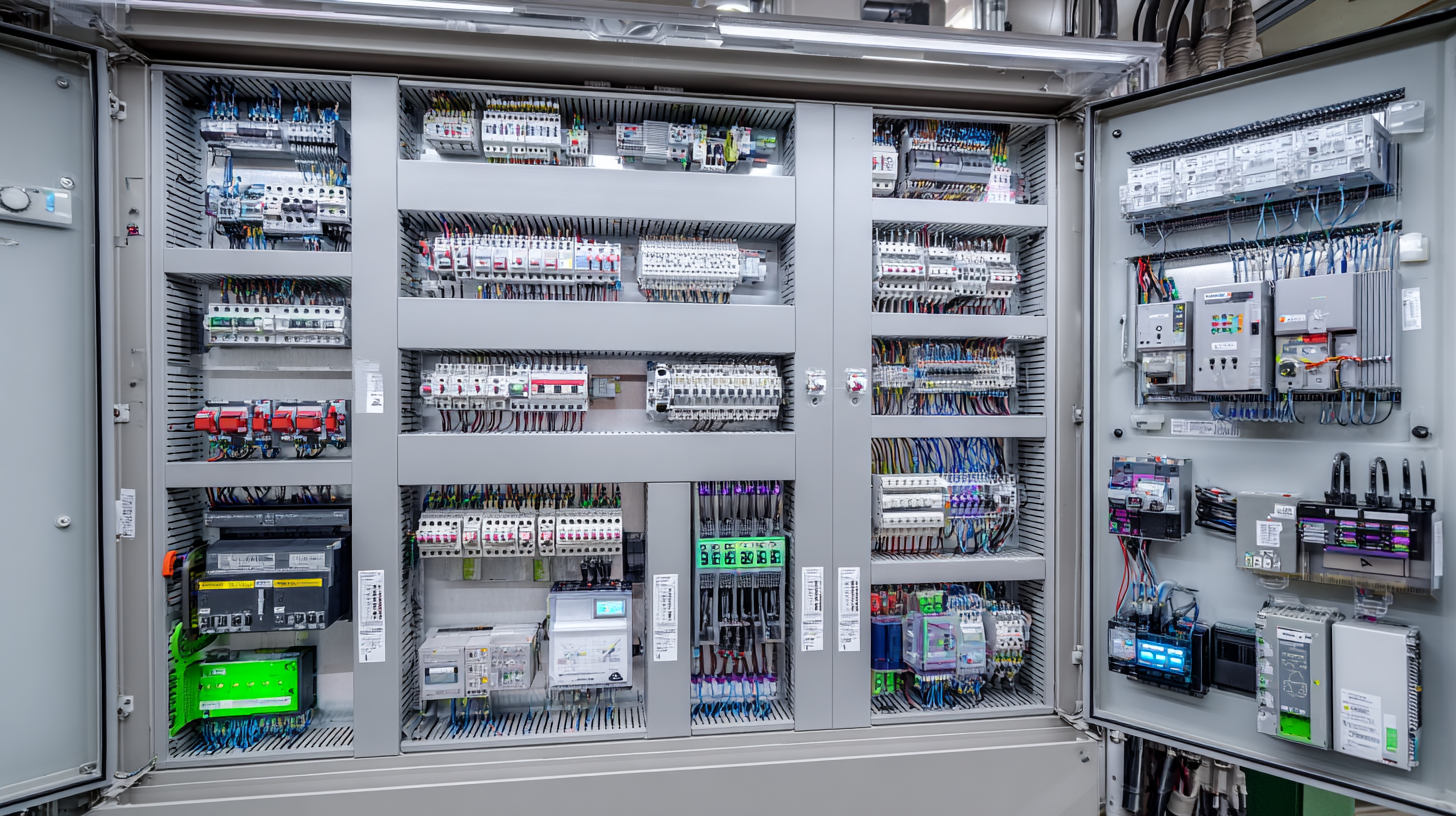

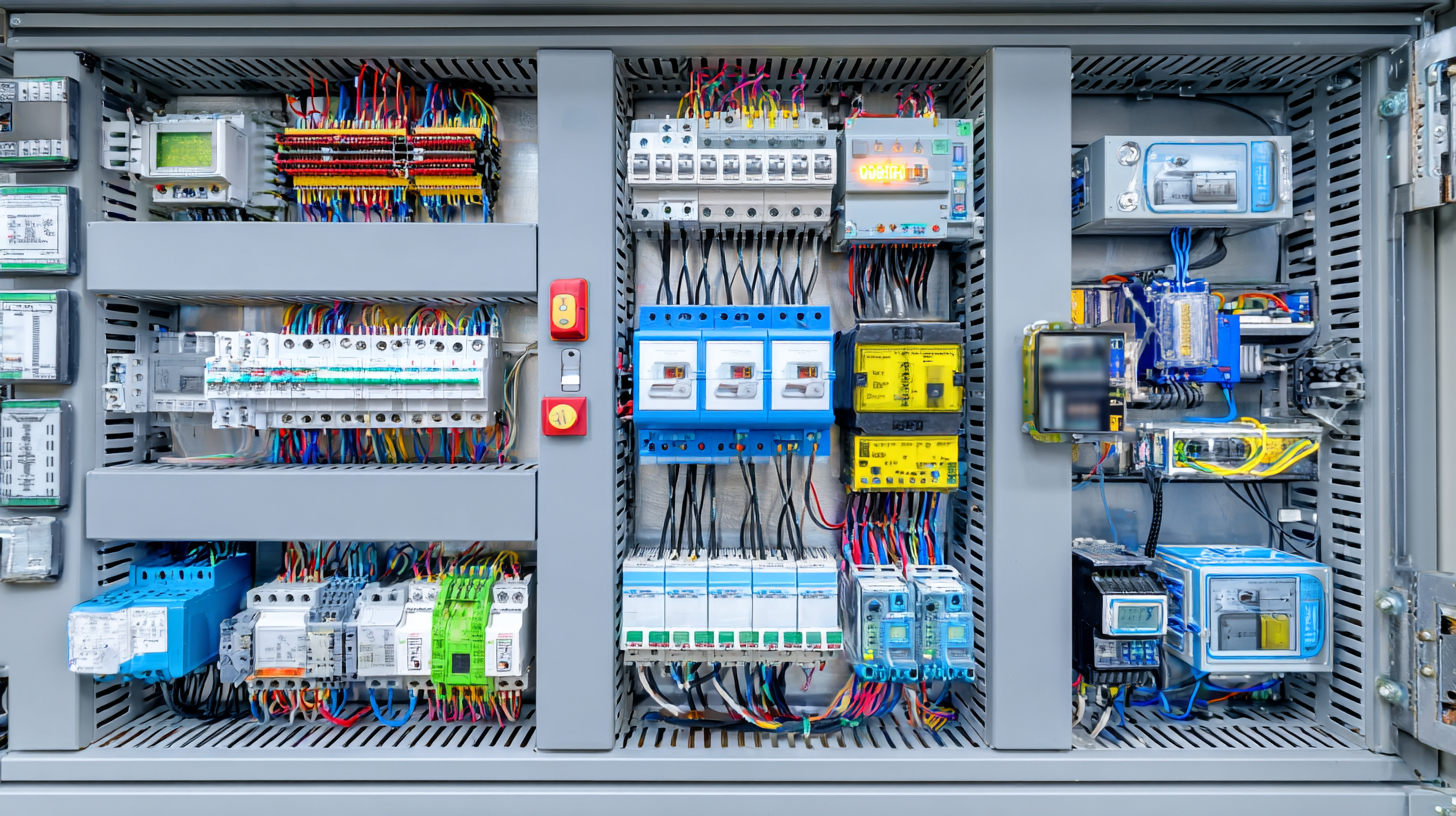

In today’s rapidly evolving industrial landscape, the role of Programmable Logic Controllers (PLC) in control panels has taken center stage in the realm of modern automation. The integration of PLC in control panel design has not only enhanced operational efficiency but has also paved the way for innovative applications that streamline processes across various sectors. As industries strive for greater flexibility and responsiveness, understanding how to effectively implement PLC in control panel systems becomes crucial. This guide explores the innovative applications and best practices for leveraging PLC technology in control panels, providing insights into their transformative potential. From optimizing machinery operations to ensuring seamless communication between devices, the structured implementation of PLC in control panels is essential for harnessing the full capabilities of automation, ultimately leading to improved productivity and reduced operational costs.

As automation continues to evolve, programmable logic controllers (PLCs) are at the forefront of advanced control panel design. Recent market reports suggest that the PLC market is expected to grow to approximately USD 25.3 billion by 2026, driven by innovations in industrial automation and the increasing adoption of IoT technologies. One of the emerging trends is the integration of smart technology within PLCs, enabling real-time data processing and enhanced control capabilities. This is particularly relevant for industries such as manufacturing, where optimizing efficiency and reducing downtime are critical.

Additionally, the shift toward modular PLC systems is gaining momentum. These systems allow for flexible configurations tailored to specific applications, significantly enhancing the adaptability of control panels in various environments. According to a recent study by Research and Markets, modular PLCs are anticipated to capture a significant share of the market, with their scalability and user-friendly interfaces meeting the demands of modern automation.

**Tips**: When designing control panels, consider incorporating IoT functionalities for improved data analytics and remote monitoring capabilities. Furthermore, choose modular PLCs that can effortlessly adapt to changing operational needs, ensuring longevity and cost-effectiveness in your automation systems. Embracing these trends will not only streamline processes but also future-proof your automation solutions.

The integration of the Internet of Things (IoT) in Programmable Logic Controller (PLC) systems is revolutionizing modern automation. According to a recent report by MarketsandMarkets, the IoT in industrial applications is expected to grow from USD 78.7 billion in 2021 to USD 110.6 billion by 2026, reflecting a compound annual growth rate (CAGR) of 7.3%. This growth highlights the critical role that IoT plays in enhancing automation efficiency. By connecting PLC systems to IoT devices, manufacturers can achieve real-time data collection and analysis, leading to improved decision-making and operational efficiency.

Furthermore, IoT-enabled PLC systems facilitate predictive maintenance, which can significantly reduce downtime and repair costs. A study by McKinsey & Company estimates that predictive maintenance can reduce maintenance costs by 10% to 40% and unplanned downtime by 50% to 60%. This ability to predict equipment failure before it occurs not only minimizes disruptions but also extends the lifespan of assets. The seamless data flow between PLCs and IoT devices empowers operators with valuable insights and analytics, optimizing production processes and fostering a proactive approach to resource management.

In the realm of modern automation, the choice between open-source and proprietary programmable logic controllers (PLCs) is crucial for effective control panel design. Open-source PLC solutions stand out for their flexibility and cost-effectiveness. They enable users to modify the source code, which can be a game changer for companies looking to tailor their automation processes without being locked into a vendor's ecosystem. However, the lack of dedicated technical support can pose challenges, particularly for less experienced teams.

In the realm of modern automation, the choice between open-source and proprietary programmable logic controllers (PLCs) is crucial for effective control panel design. Open-source PLC solutions stand out for their flexibility and cost-effectiveness. They enable users to modify the source code, which can be a game changer for companies looking to tailor their automation processes without being locked into a vendor's ecosystem. However, the lack of dedicated technical support can pose challenges, particularly for less experienced teams.

On the other hand, proprietary PLCs often offer robust support and seamless integration with existing systems, making them an attractive option for businesses prioritizing reliability and vendor assistance. While they typically come with higher initial costs, the comprehensive features and security measures provided can justify the investment. Companies must weigh these factors carefully to determine which solution aligns best with their operational needs and budget constraints.

Tips: When considering PLC solutions, assess your team’s expertise and project requirements. If your organization is open to development and has the skills, exploring open-source PLCs might lead to innovative automation solutions. Conversely, if you need reliable support and quick deployment, opting for a proprietary PLC could be the better path. Always conduct thorough research and consider conducting pilot tests before making a final decision.

The advent of Industry 4.0 has revolutionized the landscape of manufacturing, significantly impacting PLC-based control systems. According to a recent report by the International Data Corporation (IDC), 75% of manufacturers have already adopted smart manufacturing technologies, with a substantial percentage integrating PLCs into their automated systems. This shift not only enhances the efficiency and accuracy of manufacturing processes but also allows for real-time data collection and analysis, paving the way for predictive maintenance and reduced downtime.

To maximize the benefits of PLCs in the era of Industry 4.0, manufacturers should consider implementing a modular design approach for control panels. This strategy enables easy scalability and adaptability to changing production demands. Furthermore, embracing IoT integration within PLC systems can significantly improve monitoring capabilities, leading to better decision-making.

Tips: Always ensure that PLC firmware is updated to leverage the latest features and security protocols. Additionally, invest in training programs for staff to better understand the functionalities of advanced PLC applications. This investment not only enhances operational efficiency but also fosters a culture of continuous improvement within the organization.

In recent years, the integration of Programmable Logic Controllers (PLCs) in smart building automation has revolutionized how facilities manage energy, security, and overall operational efficiency. According to a report by MarketsandMarkets, the global smart building market is expected to grow from $81.57 billion in 2020 to $195.89 billion by 2025, showcasing a compound annual growth rate (CAGR) of 19.3%. This growth is significantly attributed to the innovative applications of PLCs, which enable seamless integration of various building management systems.

One notable case study is the implementation of advanced PLC systems in a newly constructed smart office complex in Singapore. By utilizing PLCs, the building was able to automate lighting, HVAC, and security protocols, resulting in a 30% reduction in energy consumption compared to traditional systems. This system not only enhances comfort for occupants but also aligns with sustainability goals critical in today’s urban development. Additionally, another project in Germany demonstrated the ability of PLCs to facilitate real-time monitoring and predictive maintenance, reducing operational downtime by up to 25%. These innovations underline the critical role of PLC technology in advancing modern automation, ensuring buildings are not only smarter but also more efficient.

| Application Area | PLC Innovation Type | Benefits Realized | Case Study Highlights |

|---|---|---|---|

| Lighting Control | Adaptive Control Algorithms | Energy Savings, Enhanced Comfort | Dynamic lighting adjustments based on occupancy and time of day. |

| HVAC Management | Predictive Maintenance Algorithms | Reduced Downtime, Operational Efficiency | Integrated HVAC systems that predict failures and optimize performance. |

| Security Systems | Real-time Monitoring and Alerts | Enhanced Safety, Rapid Response | PLC-driven integration of CCTV, alarms, and access controls. |

| Energy Management | Demand Response Strategies | Cost Reduction, Peak Shaving | Dynamic adjustments to energy usage based on grid demand signals. |