In the evolving landscape of electrical engineering, the selection of a Current Transformer Cabinet is pivotal for ensuring both the safety and efficiency of power systems. According to industry statistics, over 70% of electrical failures can be traced back to inadequate transformer protection and installation practices. The right Current Transformer Cabinet not only safeguards the integrity of your transformers but is also a key factor in optimizing energy distribution and minimizing downtime.

With the global market for transformer cabinets projected to reach $2 billion by 2025, understanding the essential criteria for selecting the most suitable cabinet becomes increasingly vital. This blog will provide ten essential tips to guide engineers and project managers in making informed decisions, thereby enhancing overall system reliability and performance.

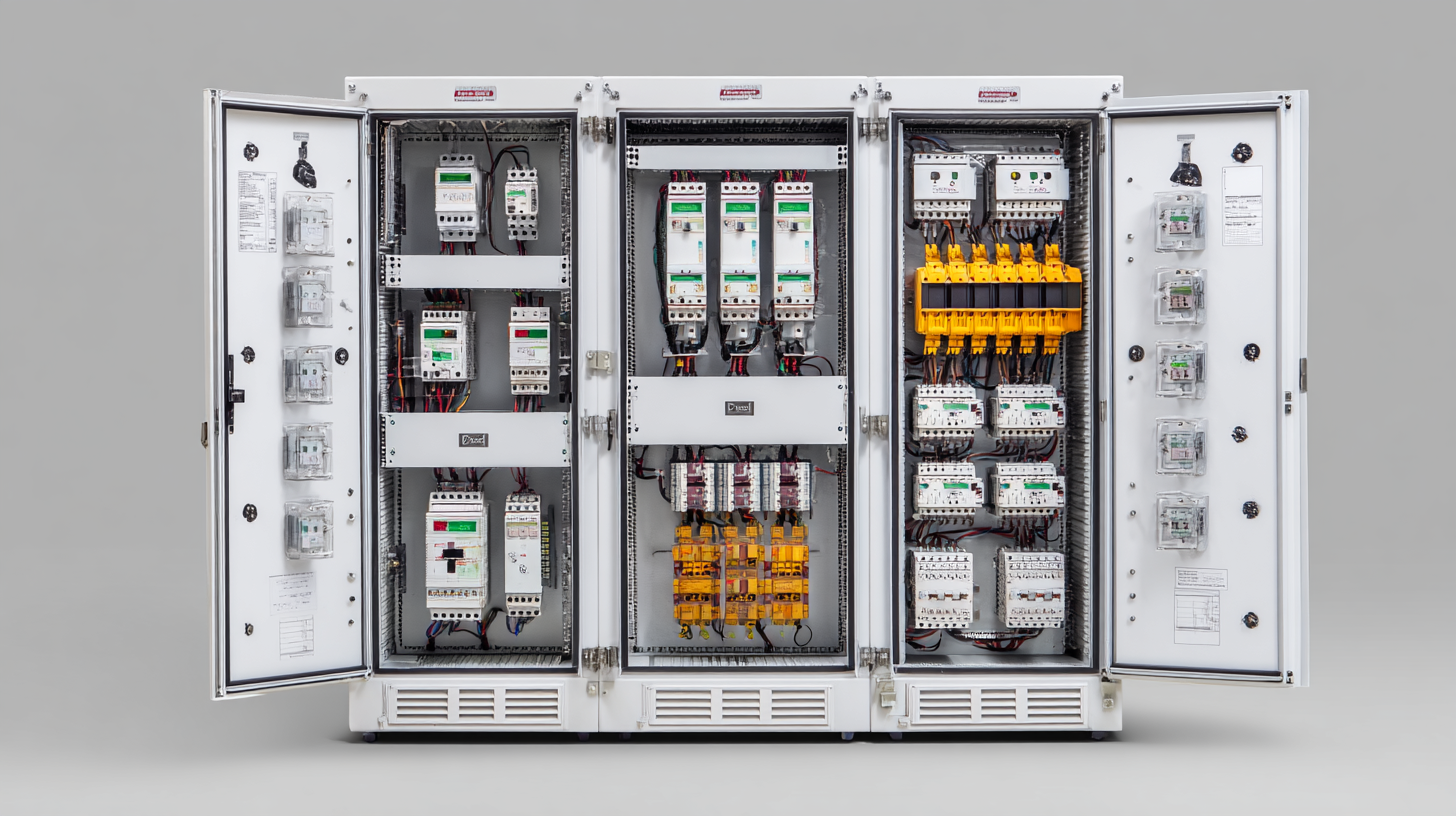

When selecting the right current transformer cabinet, it is crucial to focus on several key factors to ensure optimal performance and longevity. Firstly, consider the size and capacity of the cabinet to match your installation requirements. A well-sized cabinet will not only accommodate the current transformers but also allow for adequate ventilation and maintenance access. Additionally, check for compliance with industry standards, as this can impact the reliability and safety of the installation.

Another important factor is the material and construction of the cabinet. High-quality materials can withstand environmental challenges, such as humidity and temperature variations, which are important for maintaining the integrity of electrical components. Furthermore, think about the cabinet's design in terms of cable management and accessibility, as a well-organized layout can enhance maintenance efficiency. Lastly, evaluating the cabinet's security features is essential to protect against unauthorized access, ensuring the safety of both personnel and equipment.

| Factor | Description | Importance Level | Considerations |

|---|---|---|---|

| Load Capacity | Ensure the cabinet can handle the current load. | High | Specify maximum load requirements. |

| Size and Space | Dimensions should fit within your installation area. | Medium | Measure installation space accurately. |

| Material | Durable materials can withstand environmental conditions. | High | Consider weather-resistant options for outdoor use. |

| Ventilation | Proper airflow prevents overheating. | High | Check for adequate venting features. |

| Accessibility | Easy access for maintenance and inspection. | Medium | Ensure doors and panels can be easily opened. |

| Protection Level | Select cabinets with appropriate IP rating. | High | Assess environmental exposure risks. |

| Compliance Standards | Ensure adherence to local and international safety standards. | High | Review regulations relevant to your location. |

| Cost | Balance quality with budget constraints. | Medium | Research various pricing options. |

| Warranty and Support | Look for products with strong warranty and customer support. | Medium | Check terms of warranty and service availability. |

| Future Scalability | Consider if the cabinet can accommodate future expansions. | Medium | Evaluate potential growth of your electrical system. |

When selecting the right current transformer (CT) cabinet, understanding the role of ratings and specifications is paramount. The ratings of a current transformer, including its accuracy class and burden capacity, directly influence its performance in power system applications. According to the International Electrotechnical Commission (IEC) standards, a Class 1 transformer can deliver an accuracy of 1% for primary currents, making it ideal for utility metering applications. Depending on the intended use, a higher accuracy class may be necessary, particularly in scenarios that require precise measurements for billing and energy management.

Specifications like insulation level and temperature rating also play a critical role in transformer selection. The IEEE C57.12.00 standard describes insulation classes that ensure the transformer operates effectively under varying environmental conditions. For instance, a CT cabinet with a design temperature rating of -20°C to 40°C is suitable for most indoor applications, while those rated for extreme temperatures may be required in harsher outdoor environments. An analysis by the Electrical Apparatus Service Association indicates that selecting a transformer with appropriate specifications can lead to a more reliable operation and significantly lower maintenance costs, enhancing overall system efficiency.

When selecting a current transformer cabinet, understanding the importance of environmental protection ratings cannot be overstated. These ratings provide critical insights into how well a cabinet can withstand environmental factors such as moisture, dust, and extreme temperatures. For instance, cabinets with an IP (Ingress Protection) rating of IP65 are designed to prevent dust ingress and resist low-pressure water jets, making them suitable for outdoor installations or locations with high humidity. According to industry reports, approximately 30% of electrical failures in outdoor transformer installations can be attributed to inadequate environmental protection measures.

Additionally, environmental ratings can also indicate the material and construction quality of the cabinet, which directly impacts its longevity and reliability. Materials that are corrosion-resistant and designed for harsh environments enhance the lifespan of the transformer, ensuring consistent performance. Recent studies suggest that investing in cabinets with higher environmental ratings could reduce maintenance costs by as much as 20%, thereby significantly increasing the return on investment over the equipment's operational life. Understanding these factors is essential for making informed decisions that will ultimately protect both your equipment and the environment.

When selecting the right current transformer cabinet, the size of the cabinet plays a critical role in installation and maintenance efficiency. A well-sized cabinet can streamline the installation process, ensuring that all components fit seamlessly without unnecessary modifications. This is particularly important as the commercial refrigeration equipment market continues to grow, with projected sizes reaching USD 67.80 billion by 2033. Companies are increasingly focusing on optimizing their equipment setups for better operational efficiency, and the cabinet dimensions can significantly influence this outcome.

Moreover, the impact of cabinet size extends beyond installation; it directly affects maintenance capabilities. Sufficient space allows technicians to access equipment comfortably, perform inspections, and execute repairs without complications. With the emerging demand for HVAC systems, projected to achieve substantial growth by 2033, having a current transformer cabinet that can accommodate these changes while facilitating ease of access will be imperative. Properly sized cabinets not only enhance efficiency but also contribute to lower operational costs in the long term, making their selection a central factor for businesses aiming to maintain competitive advantages in evolving markets.

When selecting the right current transformer cabinet, it's crucial to evaluate not only the technical specifications but also the cost-benefit ratio of different materials. Given the recent developments in the energy sector, particularly with the rising costs associated with solar energy projects due to policy changes, making informed decisions about infrastructure becomes even more significant. The materials used for current transformer cabinets can directly affect both initial costs and long-term performance, especially in environments where efficiency is essential.

With the government's recent cut to solar metering benefits, which has significantly reduced incentives while increasing electricity costs, the financial viability of current transformer installations needs careful consideration. Opting for cabinets made of high-quality, durable materials may incur higher upfront costs but can lead to substantial savings in maintenance and replacement over time.

As organizations look to optimize energy production from renewable sources like the newly assessed solar PV projects, investing in the right current transformer cabinets can play a pivotal role in ensuring sustained energy yield and cost-effectiveness in the long run.