When it comes to selecting the right distribution board for your electrical needs, understanding the essential features can make all the difference. According to industry expert John Smith, a veteran electrical engineer with over 20 years of experience, "Choosing the right distribution board is not just about functionality; it’s about ensuring safety and efficiency in your electrical system." With various options available on the market, consumers often find themselves overwhelmed by the choices, making it crucial to know what to prioritize.

The distribution board, also known as a panel board, plays a vital role in the distribution of electrical power to different circuits, safeguarding homes and businesses from overload and potential hazards. As we delve into the top ten features that should influence your decision, we aim to equip you with the necessary knowledge to make an informed choice that meets your specific requirements. By focusing on key elements such as load capacity, safety mechanisms, and adaptability, you can ensure that your distribution board not only fulfills your current electrical demands but also accommodates future growth and changes in your setup.

When selecting a distribution board, one of the most crucial aspects to consider is the voltage rating. According to the International Electrotechnical Commission (IEC), distribution boards must be rated according to the specific electrical environment in which they will operate. For residential applications, a standard voltage rating of 230V is typical, while industrial facilities may require boards rated for higher voltages, often up to 415V or more. This distinction is critical, as choosing the wrong voltage can lead to equipment failures, safety hazards, and significant downtime.

The need for proper voltage rating extends beyond mere compatibility; it influences system efficiency and longevity. A study by the Electrical Contractors Association (ECA) reported that under-rated boards can cause overheating and increased energy losses, reducing overall system efficiency by as much as 30%. Additionally, exceeding the voltage rating can lead to insulation breakdown and catastrophic failures. Therefore, it is fundamental to assess not only the current load requirements but also any potential future upgrades that may necessitate a higher voltage rating, ensuring both safety and reliability in electrical distribution.

When selecting a distribution board for your electrical needs, understanding the load capacity is paramount. Load capacity refers to the total amount of electrical load that a distribution board can safely handle, and it is critical for ensuring reliable and safe electrical distribution. According to the National Electrical Manufacturers Association (NEMA), a well-sized distribution board can significantly reduce the risk of overheating and electrical failures, which can lead to costly downtimes and potential hazards. Therefore, accurately assessing your load requirements is essential before making a purchase.

A study by the Institute of Electrical and Electronics Engineers (IEEE) highlighted that over 40% of electrical failures in commercial settings are linked to underestimating load capacity. This underscores the importance of considering both current and future electrical demands. Typically, distribution boards should be designed to operate at 80% of their maximum rated capacity to allow for any unforeseen surges. This guideline helps in enhancing the durability of the system and ensuring its reliability over time. By paying close attention to load capacity, you can significantly enhance the efficiency and safety of your electrical distribution system.

When selecting a distribution board, evaluating the material and durability is crucial for ensuring operational longevity. A study by Research and Markets indicates that the global electrical distribution board market is expected to grow at a compound annual growth rate (CAGR) of 5.7% from 2021 to 2026, driven by demand for durable and reliable electrical solutions. This suggests that industry professionals increasingly prioritize materials that withstand harsh conditions, such as high humidity and temperature fluctuations.

The most common materials used in distribution boards are metal and plastic. Metal boards, often made from galvanized steel or aluminum, offer superior strength and resistance to environmental factors. According to the National Electric Manufacturers Association (NEMA), rightly chosen metal enclosures can significantly enhance lifespan, with an average durability increase of up to 25% compared to standard plastic options. Additionally, advancements in corrosion-resistant coatings allow for superior protection in various applications, particularly in industrial settings where exposure to harsh chemicals is common.

Considering durability, compliance with industry standards such as the IEC 61439 is essential, as it lays down requirements for low-voltage switchgear and control gear assemblies. Boards that meet these standards are rigorously tested for factors including thermal cycling and corrosion resistance. By prioritizing high-quality materials and adherence to stringent standards, users can ensure that their distribution boards provide reliable performance and longevity, ultimately reducing maintenance costs and enhancing safety.

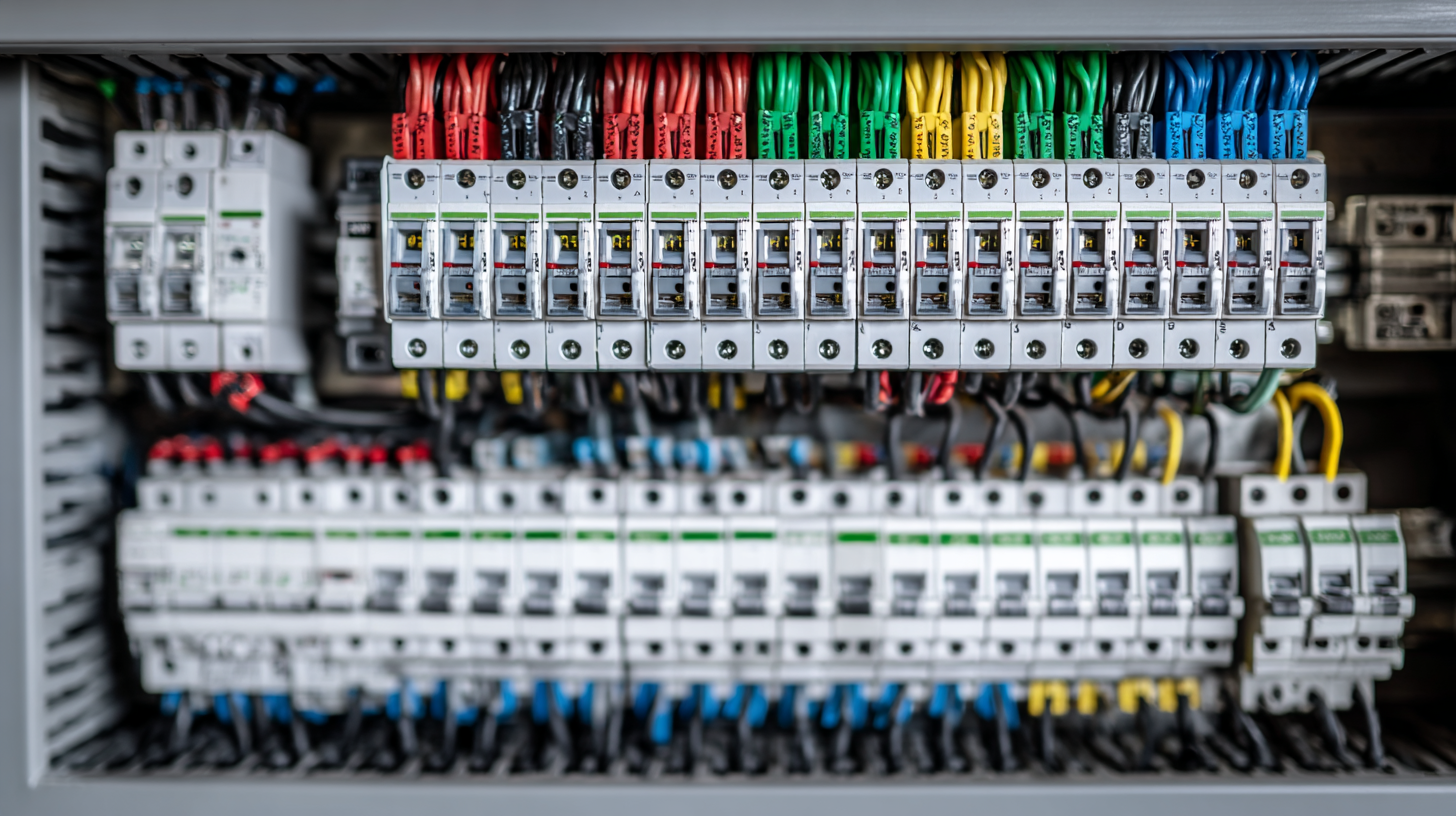

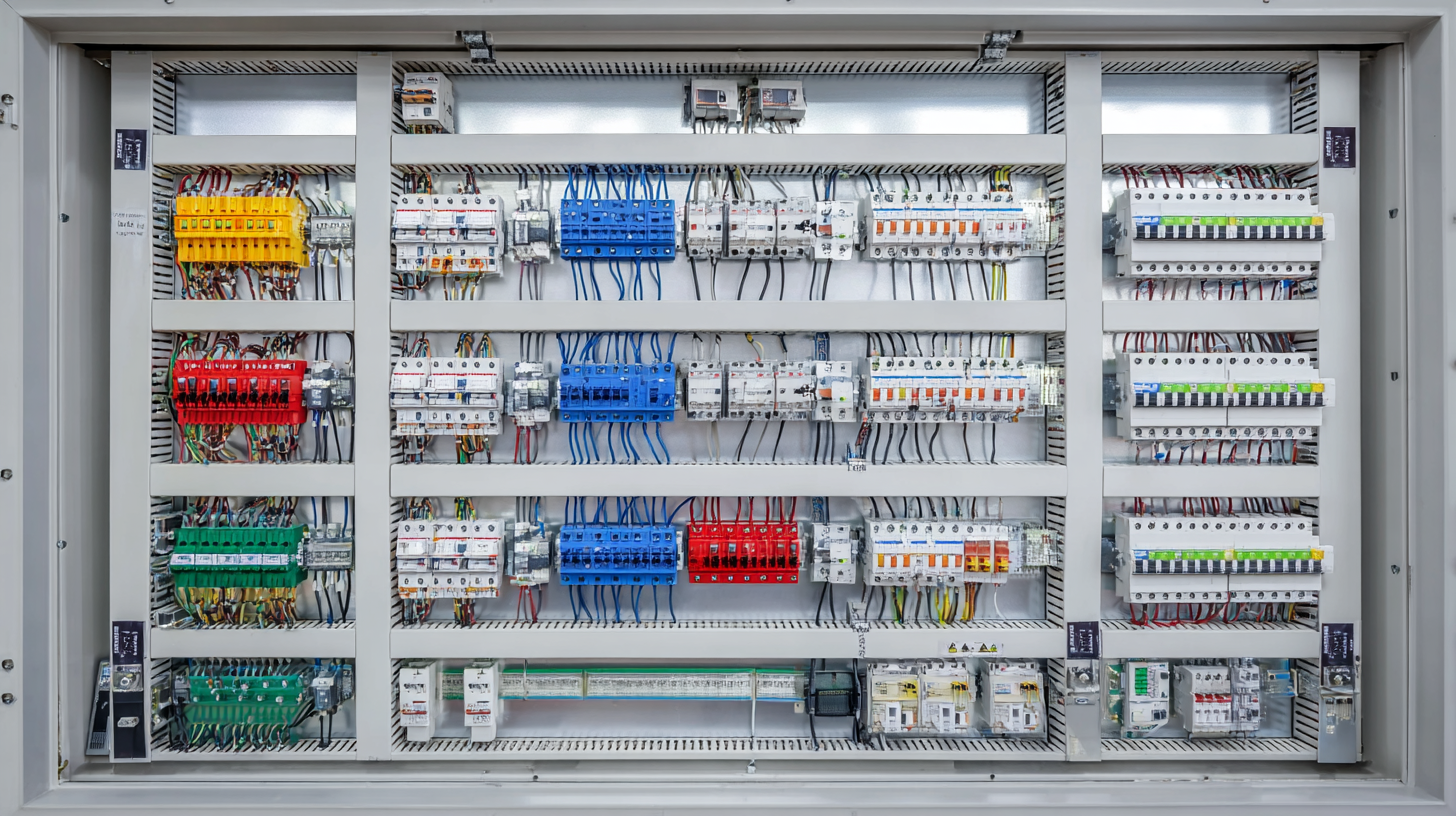

When selecting a distribution board, safety features play a critical role in ensuring both effectiveness and reliability. According to a report by the International Electrotechnical Commission (IEC), electrical safety incidents can be significantly reduced by 40-50% when utilizing distribution boards equipped with advanced protective devices such as Residual Current Devices (RCDs) and Miniature Circuit Breakers (MCBs). These devices provide essential protection against electrical faults, preventing potential hazards such as electric shocks and fire hazards.

Moreover, integrating features like surge protection devices (SPDs) is crucial in enhancing the longevity and performance of electrical systems. The 2022 Global Electrical Safety Report indicated that over 30% of electrical failures and malfunctions stem from voltage surges. By incorporating SPDs within distribution boards, users can mitigate the risks associated with power surges, thereby protecting sensitive equipment. The role of safety features in distribution boards is not just about compliance; it significantly boosts operational efficiency and security in both residential and commercial electrical installations.

When selecting a distribution board, examining its compatibility with existing electrical systems is paramount. According to the Electrical Safety Foundation International (ESFI), over 60% of electrical fires result from improper installations or outdated equipment. This statistic highlights the necessity for thorough compatibility assessments to ensure that the new distribution board integrates seamlessly with your current setup and adheres to local codes and regulations.

Additionally, modern advancements in smart technology need to be factored in. The global smart home market is projected to reach $174 billion by 2025, as per a report from Grand View Research. Distribution boards that support digital monitoring and management will not only enhance operational efficiency but also future-proof your electrical infrastructure. Therefore, when considering a new distribution board, evaluate its support for current technological trends and ensure it can accommodate future expansions or modifications. This proactive approach can help mitigate potential safety hazards and optimize performance in your electrical system.

| Feature | Description | Importance | Considerations |

|---|---|---|---|

| Compatibility | Ensure it integrates seamlessly with your existing systems. | High | Check voltage ratings and system types. |

| Rated Current | Select a board that can handle the required current load. | High | Assess total load calculations. |

| Space | Ensure adequate physical space for installation. | Medium | Measure available installation area accurately. |

| Protection Rating | Check IP rating for dust and water resistance. | High | Consider environmental conditions. |

| Busbar System | Opt for a reliable busbar approach for electrical distribution. | Medium | Evaluate current-carrying capacity. |

| Ease of Access | Design should allow for easy maintenance and operation. | Medium | Plan for clearance and accessibility. |

| Circuit Protection | Integrate protective devices to safeguard circuits. | High | Choose правильно соответствующие устройства защиты. |

| Future Expansion | Allow room for potential future installations. | Medium | Anticipate future needs and expansions. |

| Quality Standards | Ensure compliance with local standards and regulations. | High | Review certification and compliance documents. |

| Cost | Consider budget without compromising quality. | Medium | Analyze total cost of ownership. |